Induction melting furnacesKOZYREV Research and Production Enterprise

• For ferrous, non-ferrous and precious metals and alloys

• Capacity from 60 to 6000 kg

• Power from 100 to 3500 kW

ОLeave a request

and our specialist will contact you

Select the parameters of your future oven:

One last step left! Fill out the form and you will be contacted by our specialist who will tell you about the furnace options that suit you

By clicking you consent to the processing of your personal data

Request

Select the parameters of your future oven:

One last step left! Fill out the form and you will be contacted by our specialist who will tell you about the furnace options that suit you

By clicking you consent to the processing of your personal data

We increase your profit with our equipment

We manufacture unique equipment at our own production facility in Chelyabinsk city

Full range of works (from manufacturing to indefinite technical assistance)

We increase your profit with our equipment

We manufacture unique equipment at our own production facility in Chelyabinsk city

Full range of works (from manufacturing to indefinite technical assistance)

Your key benefits

Contact the KOZYREV Research and Production Enterprise, and you will learn how to melt metal and get significantly more profit than your competitors:

More profit from energy savings

More profits from the operation without any downtime

More profit from a long service life

More profit from energy savings

Thanks to a deep study of all the details, we managed to achieve significant reduction power losses (up to 25%!) in the entire chain, from the power source to the melting point.

You spend significantly less resources per 1 ton of melted material than your competitors!

And therefore - you earn more.

More profits from the operation without any downtime

Due to successful circuit solutions and expert design know-how, we managed to increase the margin of safety and reduce the load on the most critical elements of the system, such as the thyristors of the inverter and of rectifier, the resistance of RC chains, the hearth and upper heat resistant plates, the axes of rotation of the lifting cylinder actuators, the metal body of the melting unit, and many others.

Our furnaces are working at full capacity and without stopping!

More profit from a long service life

We are not low-cost manufacturers, and therefore we do not have a goal to create and sell the cheapest furnace. But we have the opportunity to offer you a much more interesting product – a furnace that works for decades. After all, we use the most reliable components of the world's leading brands (ABB, SIEMENS, SCHNEIDERELECTRIC, Kendeil, Proton-Electrotex and others), as well as the highest quality materials (oxygen-free copper, M1 electrical copper, high-quality certified austenitic non-magnetic steel, highly reliable heat-resistant concrete.

Service life is at least four times the payback period.

More profit from energy savings

More profits from the operation

without any downtime

More profit from a long service life

More profit from energy savings

Thanks to a deep study of all the details, we managed to achieve significant reduction power losses (up to 25%!) in the entire chain, from the power source to the melting point.

You spend significantly less resources per 1 ton of melted material than your competitors!

And therefore - you earn more.

More profits from the operation without any downtime

Due to successful circuit solutions and expert design know-how, we managed to increase the margin of safety and reduce the load on the most critical elements of the system, such as the thyristors of the inverter and of rectifier, the resistance of RC chains, the hearth and upper heat resistant plates, the axes of rotation of the lifting cylinder actuators, the metal body of the melting unit, and many others.

Our furnaces are working at full capacity and without stopping!

More profit from a long service life

We are not low-cost manufacturers, and therefore we do not have a goal to create and sell the cheapest furnace.But we have the opportunity to offer you a much more interesting product – a furnace that works for decades. After all, we use the most reliable components of the world's leading brands (ABB, SIEMENS, SCHNEIDERELECTRIC, Kendeil, Proton-Electrotex and others), as well as the highest quality materials (oxygen-free copper, M1 electrical copper, high-quality certified austenitic non-magnetic steel, highly reliable heat-resistant concrete.

Service life is at least four times the payback period.

Easy and safe operation:

Professional assistance at every stage of operation

Training your staff

Production and employees safety

Professional assistance at every stage of operation

You will never be left alone with the problems that can arise when working with complex equipment.

Our specialists will always help you and provide you with technical support at every stage of your work. From manufacturing and delivery to installation and operation.

We will also provide unlimited post-sale technical support, no matter what kind of questions or problems you encounter.

Training your staff

You don't need to attract exclusive and expensive specialists for work.

You just need to train your existing employees. This will allow you to save additional money.

We will train, instruct and prepare your specialists to work professionally with our equipment.

We will teach you how to work, make adjustments and readjustments, as well as deal with equipment management.

Production and employees safety

Metal smelting is a production with a high risk level to the life and health of the employees.

Therefore, ensuring the safety of all process participants is the most important task.

This is why our furnaces are equipped with a lining control system, flow control systems, and cooling water temperature.

To prevent accidents, the furnaces are equipped with backup pumps, that allow not to stop melting process in the case of failure of the main pumps.

In the event of a power outage, a mechanical method of tilting the furnace should be provided for emergency metal draining.

Also, before delivery we organize a tests of electrical insulation and tripping event.

Thus, even in the case of a failure, breakdown, or force majeure, none of your specialists will be harmed under any circumstances.

Professional assistance

at every stage of operation

Training

your staff

Production and employees

safety

Professional assistance at every stage of operation

You will never be left alone with the problems that can arise when working with complex equipment.

Our specialists will always help you and provide you with technical support at every stage of your work. From manufacturing and delivery to installation and operation.

We will also provide unlimited post-sale technical support, no matter what kind of questions or problems you encounter.

Training your staff

You don't need to attract exclusive and expensive specialists for work.

You just need to train your existing employees. This will allow you to save additional money.

We will train, instruct and prepare your specialists to work professionally with our equipment.

We will teach you how to work, make adjustments and readjustments, as well as deal with equipment management.

Безопасность производства и сотрудников

Metal smelting is a production with a high risk level to the life and health of the employees.

Therefore, ensuring the safety of all process participants is the most important task.

This is why our furnaces are equipped with a lining control system, flow control systems, and cooling water temperature.

To prevent accidents, the furnaces are equipped with backup pumps, that allow not to stop melting process in the case of failure of the main pumps.

In the event of a power outage, a mechanical method of tilting the furnace should be provided for emergency metal draining.

Also, before delivery we organize a tests of electrical insulation and tripping event.

Thus, even in the case of a failure, breakdown, or force majeure, none of your specialists will be harmed under any circumstances.

Russian production, reliable counterparty and delivery on time:

Equipment made in Russia

Reliable supplier

Equipment is made strictly according to the technical requirements, delivery accomplish on time

Equipment made in Russia

We manufacture high-quality and reliable equipment at our own production facilities in Chelyabinsk city, in an area of 5000 m2. In addition to induction melting furnaces, we develop:

- Inductors for heating,

- Quenching and water-cooled transformers,

- Capacitors,

- Washing plants,

- and other equipment.

We use a lot of technological best practices and always adhere to the principle of technology continuous improvement.

A solid production base and many years of experience allow us to ensure a high level of quality and high performance of our equipment.

Reliable supplier

- Many years of experience and a huge amount of knowledge,

- More than 150 completed projects, including international one (Austria),

- Experience in manufacturing equipment for the most serious industries, including the nuclear and military industries,

- Articles and publications, as well as a technical library on our site inductor.su,

- Impeccable reputation,

- Permanent participation in Russian and European specialized exhibitions

Confirm our high professionalism, expert approach to equipment development and the high quality of our work.

We are not a "noname" or "short-lived thing" enterprise who decided to earn some money on the resale of Chinese or "home-made" furnaces.

We are a serious and experienced company with a long-term development strategy!

By signing a contract with us, you get a reliable counterparty and a stable partner for many years to come.

Equipment is made strictly according to the technical requirements, delivery accomplish on time

We understand that you need equipment specifically for Your needs.

Therefore, the approval of the technical requirements is the most priority-oriented part of the work.

And then your furnace will be manufactured in exact accordance with the agreed technical requirements.

The delivery time will be minimal and also pre-agreed. From 30 days.

We will also provide with a full set of technical documentation in the Customer's language.

Equipment

made in Russia

Reliable

supplier

Equipment is made strictly according

to the technical requirements,

delivery accomplish on time

Equipment made in Russia

We manufacture high-quality and reliable equipment at our own production facilities in Chelyabinsk city, in an area of 5000 m2. In addition to induction melting furnaces, we develop::

- Inductors for heating,

- Quenching and water-cooled transformers,

- Capacitors,

- Washing plants,

- and other equipment.

We use a lot of technological best practices and always adhere to the principle of technology continuous improvement.

A solid production base and many years of experience allow us to ensure a high level of quality and high performance of our equipment.

Reliable supplier

- Many years of experience and a huge amount of knowledge,

- More than 150 completed projects, including international one (Austria),

- Experience in manufacturing equipment for the most serious industries, including the nuclear and military industries,

- Articles and publications, as well as a technical library on our site inductor.su,

- Impeccable reputation,

- Permanent participation in Russian and European specialized exhibitions

Confirm our high professionalism, expert approach to equipment development and the high quality of our work.

We are not a "noname" or "short-lived thing" enterprise who decided to earn some money on the resale of Chinese or "home-made" furnaces.

We are a serious and experienced company with a long-term development strategy!

By signing a contract with us, you get a reliable counterparty and a stable partner for many years to come.

Equipment is made strictly according to the technical requirements, delivery accomplish on time

We understand that you need equipment specifically for Your needs. Therefore, the approval of the technical requirements is the most priority-oriented part of the work.

And then your furnace will be manufactured in exact accordance with the agreed technical requirements.

The delivery time will be minimal and also pre-agreed. From 30 days. We will also provide with a full set of technical documentation in the Customer's language.

Equipment оcharacteristics and parameters

Induction melting furnace is a set that includes:

01

Thyristor frequency converter

Serves as a power source for the furnace

02

Block of contour capacitors (bank of capacitors)

Necessary for creating an electric oscillating circuit

03

Melting unit

The furnace itself, where the metal is melted

04

Inductor

Generates eddy currents in the metal, which heat the metal to high temperatures

05

Cooling system

Necessary for cooling the entire set of equipment

06

Pumping unit with

hydraulic oil

Required for hydraulic rotation of the furnace to drain metal into the bucket

07

Water-cooled cables

Are required to connect the furnace to the condensers

Request

Equipment characteristics and parameters

Induction melting furnace is a set that includes:

01

Thyristor frequency converter

Serves as a power source for the furnace

07

Water-cooled cables

Are required to connect the furnace to the condensers

02

Block of contour capacitors (bank of capacitors)

Necessary for creating an electric oscillating circuit

06

Pumping unit with hydraulic oil

Required for hydraulic rotation of the furnace to drain metal into the bucket

03

Melting unit

The furnace itself, where the metal is melted

04

Inductor

Generates eddy currents in the metal, which heat the metal to high temperatures

05

Cooling system

Necessary for cooling the entire set of equipment

Request

Standard characteristics of our furnaces:

Furnace volume: 60, 100, 150, 250, 400, 500, 750, 1000, 1500, 2000, 2500 kg.

Power: 100, 160, 200, 250, 320, 400, 500, 630, 800, 1000, 1250, 1300 kW.

A rigid structure that does not deform during operation

Number of melting units: 1, 2, 3

Availability of cooling system: Yes / No

Metals that are smelted by our furnaces:

- Ferrous (steel, cast iron),

- Non-ferrous (copper, aluminum, brass, copper zinc alloy, cupronickel, nickel, zinc),

- Precious (silver, gold, platinum, bronze),

- Ferroalloys

Leave a request

and our specialist will contact you

Leave a request and get a professional help for selection of the furnace for your tasks and budget

If you want to buy complex and non-standard equipment, whether it is an induction heating system or a furnace induction complex, then you, of course, want to trust reliable professionals.

By clicking you consent to the processing of your personal data

Choosing a furnace

Choose the parameters of your future oven:

Leave a request

and our specialist will contact you

Choose the parameters of your future oven:

ОLeave a request

and our specialist will contact you

Stages of work

Technical requirements

We find out your needs and help you prepare the correct technical task

The technical and commercial offer and the conclusion of the contract

We prepare a detailed technical and commercial offer, accord a contract and start implementing the project

Production of equipment

We begin the process of manufacturing the furnace according to the approved technical and commercial offer

Furnace testing

When the equipment is ready, it passes preliminary tests at our factory

Shipping and delivery

After the furnace is manufactured, we help deliver and install it in your production

Start-up and test smelting

The commissioning specialist checks the correctness of the entire circuit, configures the equipment, checks the correct connections, and accompanies several test smeltings

Employee training

We provide training for your employees to teach them how to use the equipment correctly

Unlimited technical support

We provide unlimited consultations by phone

Leave a request

and our specialist will contact you

Stages of work

Technical requirements

We find out your needs and help you prepare the correct technical task

The technical and commercial offer and the conclusion of the contract

We prepare a detailed technical and commercial offer, accord a contract and start implementing the project

Production of equipment

We begin the process of manufacturing the furnace according to the approved technical and commercial offer

Furnace testing

When the equipment is ready, it passes preliminary tests at our factory

Shipping and delivery

After the furnace is manufactured, we help deliver and install it in your production

Start-up and test smelting

The commissioning specialist checks the correctness of the entire circuit, configures the equipment, checks the correct connections, and accompanies several test smeltings

Employee training

We provide training for your employees to teach them how to use the equipment correctly

Unlimited technical support

We provide unlimited consultations by phone. We promptly take measures in case of warranty repairs

Request

About us

KOZYREV Research and Production Enterprise is an engineering company with production facilities in city of Chelyabinsk.

We have extensive experience (more than 35 years) in the development and manufacture of machine-building and metallurgical equipment.

We have been manufacturing induction and high-frequency equipment for more than 9 years.

We produce induction furnaces for melting ferrous (steel, cast iron), non-ferrous (copper, aluminum, etc.) and precious metals (silver, gold, platinum).

We are committed to the principle of "continuous improvement" of the technology and manufacturing process, which ultimately gives serious results in terms of greater payback, reliability and durability of our equipment.

We have implemented more than 150 projects, including international ones.

Our clients are:

- Foundry, metallurgical, machine-building, pipe, defense plants,

- Foundry-mechanical and forging-press production,

- Plants for the processing of precious metals,

- Engineering companies,

- Manufacturers of molding equipment.

Danil Kozyrev

CEO

Among our customers are "Rosatom", group of companies "GAZ", "Kalashnikov", "SUKHOI COMPANY" and many others.

Products are delivered throughout Russia and the CIS, as well as to the European Union and the middle East. If you want your equipment to bring maximum profit and serve with no break for many years, contact the KOZYREV Research and Production Enterprise.

We will solve your problem! No matter how difficult it is!

Our clients

Leave a request and get a professional help for selection of the furnace for your tasks and budget

If you want to buy complex and non-standard equipment, whether it is an induction heating system or a furnace induction complex, then you, of course, want to trust reliable professionals.

By clicking the button you consent to the processing of your personal data

By clicking you consent to the processing of your personal data

Our works

"PLANT NEXT TRADE"

OOO "FERROOMSK"

OOO "INTEGRA"

JSC "Ferroalloy"

LLC "PLANT NEXT TRADE" (LLC "Voronezh foundry»)

Implementation date: launch of the first stage in October 2015, launch of the second stage in May 2016.

Scope of delivery: 2 sets of induction furnaces for melting steel/cast iron with a capacity of 400 kg each.

The power of feeding mid–frequency generators is: 320 kW.

One of the generators is built on the ALJUEL microprocessor control system

OOO "FERROOMSK", Omsk city

Implementation date: July 2017.

Scope of delivery: the melting unit with a heater-type cooling system.

The capacity of the steel melting unit is: 250 kg.

The power of feeding mid-frequency generators is: 250 kW.

The generator is built on a microprocessor control system based on the MPU-2F controller.

OOO "INTEGRA", Chelyabinsk city

Implementation date: June 2017

Scope of delivery:

1. Set of induction furnace for melting steel/cast iron with a capacity of 500 kg. The power of feeding mid-frequency generators is 320 kW. The generator is built on a microprocessor control system based on the MPU-2F controller.

2. Set of molding equipment for casting using LFC technology (lost foam casting). Consisting of: - a knockout grate with a molding flask hydraulic turnover device; a system for pneumatic feeding of molding quartzite with two bins with a capacity of 20 tons of quartzite; a 5-coordinate vibrating table with a pneumatic lifting drive, a set of casting boxes;

3. Vacuum system consisting of: vacuum pump VVN1-6, vacuum receiver V-3m3, vacuum distributor; as well as painting, drying, model equipment.

JSC "Ferroalloy", Chelyabinsk city

Implementation date: November 2017.

Scope of delivery: induction melting furnace without cooling system, with two melting units

The capacity of steel melting units is: 500 kg

The power of feeding mid-frequency generator is: 500kW.

The generator is built on a microprocessor control system based on the MPU-2F controller.

"PLANT NEXT TRADE"

OOO "FERROOMSK",

OOO "INTEGRA"

JSC "Ferroalloy",

OOO "PLANT NEXT TRADE" (LLC "Voronezh foundry»)

Implementation date: launch of the first stage in October 2015, launch of the second stage in May 2016.

Scope of delivery: 2 sets of induction furnaces for melting steel/cast iron with a capacity of 400 kg each.

The power of feeding mid–frequency generators is 320 kW. One of the generators is built on the ALJUEL microprocessor control system

OOO "FERROOMSK", Omsk city

Implementation date: July 2017.

Scope of delivery: the melting unit with a heater-type cooling system. The capacity of the steel melting unit is 250 kg. The power of feeding mid-frequency generators is 250 kW. The generator is built on a microprocessor control system based on the MPU-2F controller.

OOO "INTEGRA", Chelyabinsk city

Implementation date: June 2017

Scope of delivery:

1. Set of induction furnace for melting steel/cast iron with a capacity of 500 kg. The power of feeding mid-frequency generators is 320 kW. The generator is built on a microprocessor control system based on the MPU-2F controller.

2. Set of molding equipment for casting using LFC technology (lost foam casting).

Consisting of: - a knockout grate with a molding flask hydraulic turnover device; a system for pneumatic feeding of molding quartzite with two bins with a capacity of 20 tons of quartzite; a 5-coordinate vibrating table with a pneumatic lifting drive, a set of casting boxes;

3. Vacuum system consisting of: vacuum pump VVN1-6, vacuum receiver V-3m3, vacuum distributor; as well as painting, drying, model equipment.

JSC "Ferroalloy", Chelyabinsk city

Implementation date: November 2017.

Scope of delivery: induction melting furnace without cooling system, with two melting units. The capacity of steel melting units is 500 kg. The power of feeding mid-frequency generator is 500kW. The generator is built on a microprocessor control system based on the MPU-2F controller.

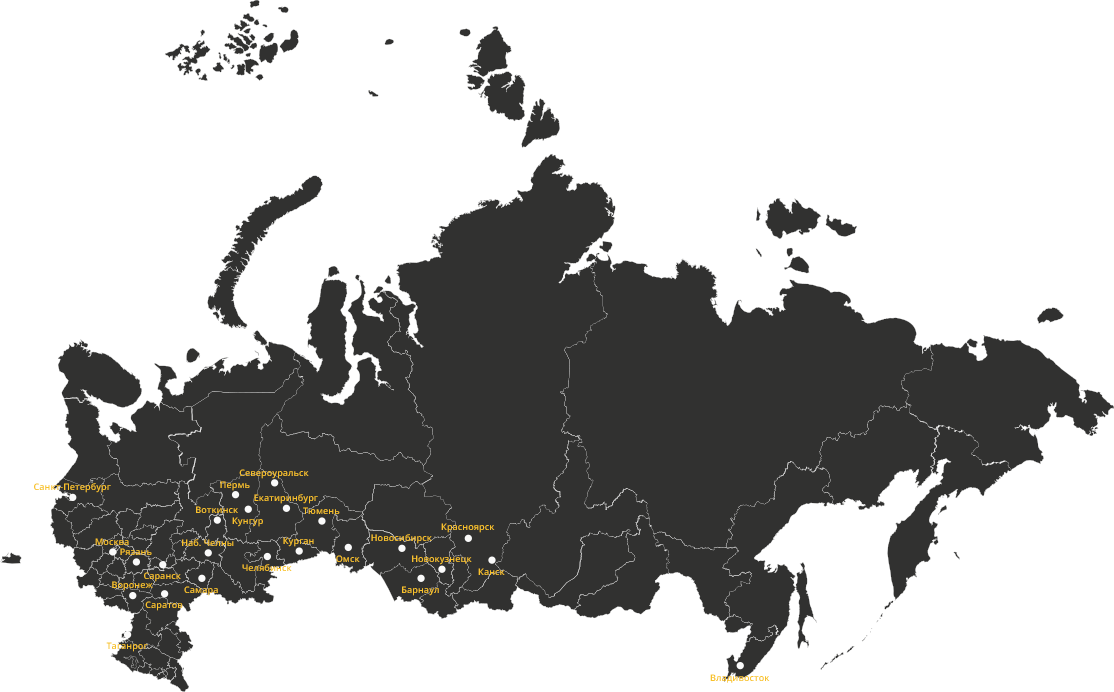

Geography of supplies

Geography of supplies

If you are interested in accessories, leave a request

Leave a request

and our specialist will contact you

If you are looking for a reliable and experienced supplier of induction equipment

KOZYREV RPE, 2020

CONTACTS

454008,Russia, Chelyabinsk

+7 (351) 711-15-40

sales@inductortech.com

Monday-Friday: 09:00 - 19:00

Политика конфиденциальности

Редактируемый текст

Данный сайт использует Cookie

Редактируемый текст